SDYW30 linear push rod CNC bending hydraulic busbar processing machine

SDYW30 Linear Push Rod CNC Bending Hydraulic Busbar Processing Machine

content

1. Appearance of the equipment

2. Basic parameters of the equipment

3. Equipment performance

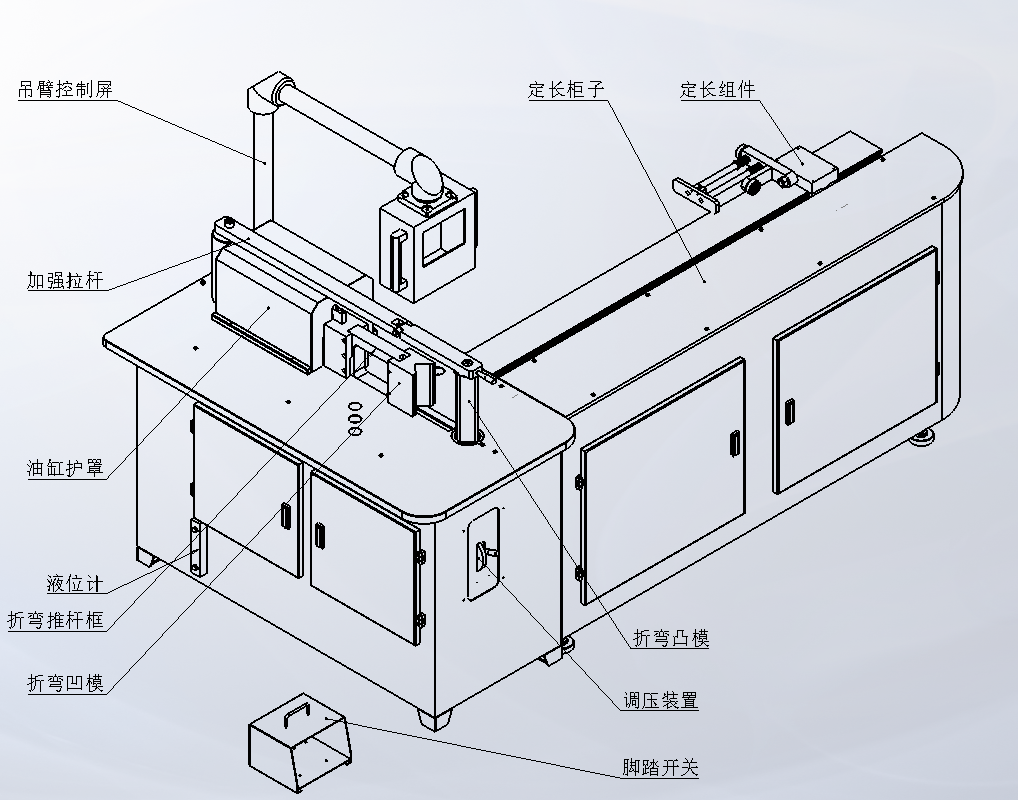

1. Appearance of the equipment:

2. Basic parameters of the equipment

| Serial number | name | numerical value | Company |

| Ⅰ | Nominal pressure | 300 | kN |

| Ⅱ | Oil pump motor power | 5.5 | kW |

| Ⅲ | Maximum bus processing specification | 160×12×6000 | mm |

| Ⅳ | Bending accuracy | ±0.5 | limit |

| Ⅴ | Control system | Independent research and development | |

| Ⅵ | Overall dimension | 2700×1500×1750 | mm |

| Ⅶ | Equipment weight | 1200 | kg |

3. Equipment performance

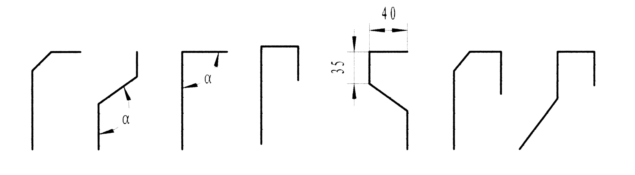

SDYW30 linear push rod CNC bending hydraulic busbar processing machine is a general-purpose multifunctional bus processing equipment machine independently developed by our factory. Its bending adopts push rod bending structure and linear numerical control bending method. To control the bending angle of the busbar, the positioning is accurate, and the repeatability is high. The machine head adopts a push-rod structure, which can avoid many interference problems during complex bending, making the bending action more convenient, freeing more restrictions on the size of the busbar, and improving the bending efficiency. Bending fixed length adopts PLC control servo motor system to realize automatic bending fixed length positioning, input the length through the numerical control system or calculate the blanking length through continuous bending to determine the bending position, and cooperate with the bending part to complete the fixed length bending work, and the positioning is accurate and fast. This machine is used to process copper and aluminum busbars of various specifications. As long as the user installs the mold, the busbar can be bent into various shapes. The bending control of this machine adopts the principle of numerical control straight line, which can bend the busbars of different angles without special molds. This machine is intended to be used for the bending function of busbars, with high production efficiency, good repeatability, and multiple uses in one machine. It is an ideal equipment for processing high and low voltage electrical busbars. The equipment is also randomly equipped with a variety of molds and accessories such as busbar vertical bending dies, small busbar short-side flat bending dies, etc., which basically meet the production requirements of users. Users can also customize molds with special specifications according to the special requirements of production. The bending geometry of the busbar is as shown in the figure below, and the legend is the minimum size of the bending (when the short side flat bending die of the small busbar is used), the maximum size is not limited.

CONTACT INFORMATION

Yunnan multifunctional fillet machine - Yunnan bus bar processing machine - Kunming copper bar processing machine

Service hotline: 0871-68310369 13608805685 18587197072

e-mail address: crazer70@qq.com

Company address: No. 1028, Haiyuan Middle Road, national high tech Industrial Development Zone, Kunming

ONLINE MESSAGE

Copyright: Kunming KUNKAI special numerical control equipment Co., Ltd. Yunnan ICP preparation No. 11004860-1 website construction: China Enterprise Power Kunming SEO